- 45% reduction in energy costs.

- 25% reduction in heater watt density

- 40% Faster Start up time

- Removable / Reusable

- Optimal Thermal Efficiency

- Tool - Free installation

SE custom made insulation jackets are designed to insulate wide variety of equipment including valves, flanges, calorifiers, strainers, separators, actuators, heat exchangers, elbow bends, etc. helping to deliver up to 97% energy conservation, and provide exceptional Thermal Conductivity properties. They are also commonly used to provide insulation against low temperature and protect personnel from burns by reducing the temperature of the exposed pipework surfaces.

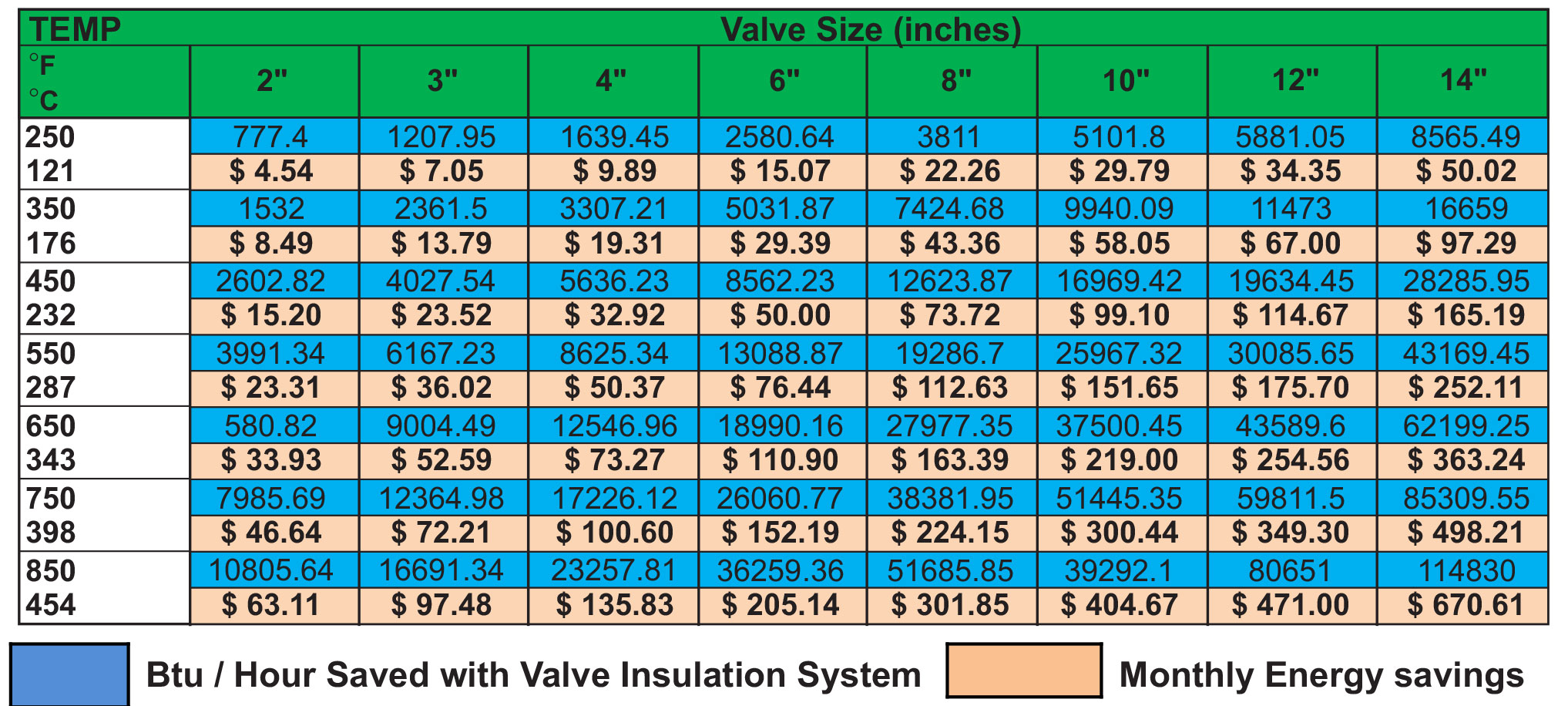

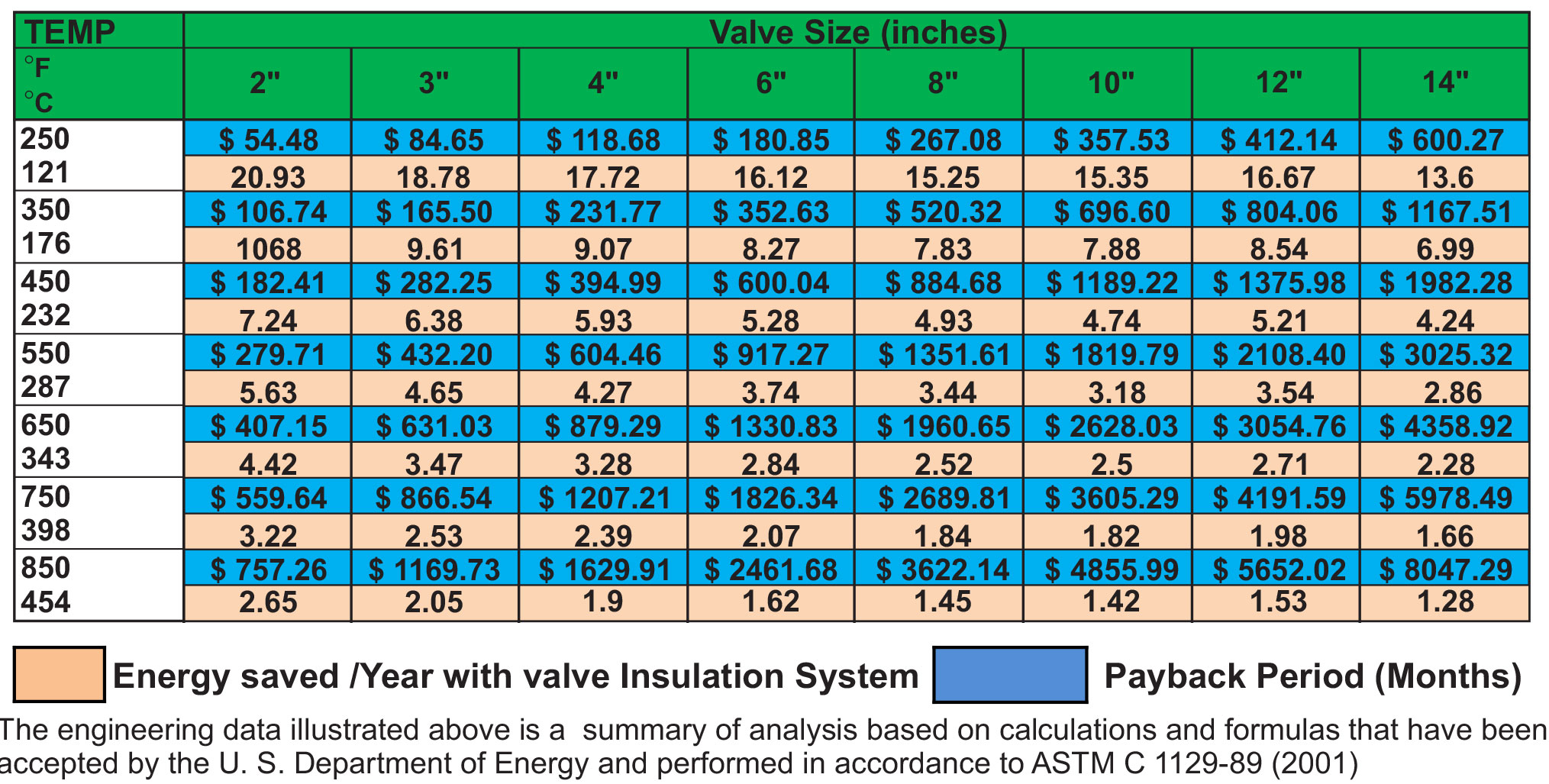

Additionally, end users enjoy an attractive return on their lnsulation system investment based\ solely on energy savings. The payback period accelerates as equipment size and operating temperature increases.

Key Benefits

SE insulation Jacket has self-contained insulation system, constructed with a high density insulation filler with a fully encapsulated outer jacketing. The outer jacketing is double sewn and binded at the closing seams. They jacketing and sewn construction ensure long lasting protection to the insulation filler.